Track & Off Track Drainage Systems

AQUA offers a comprehensive range of Track and Off-Track Drainage products to enable designers and contractors to select the most appropriate product for the site specific conditions and requirements.

Lineside drainage has just two requirements; to collect and carry away from the tracks immediate vicinity, any water received from rainfall, springs and/ or run-off from adjacent land. Since the beginning, our product range has been designed and developed in conjunction with railway engineers, to ensure the products we offer are specific to the rail industries unique criteria:

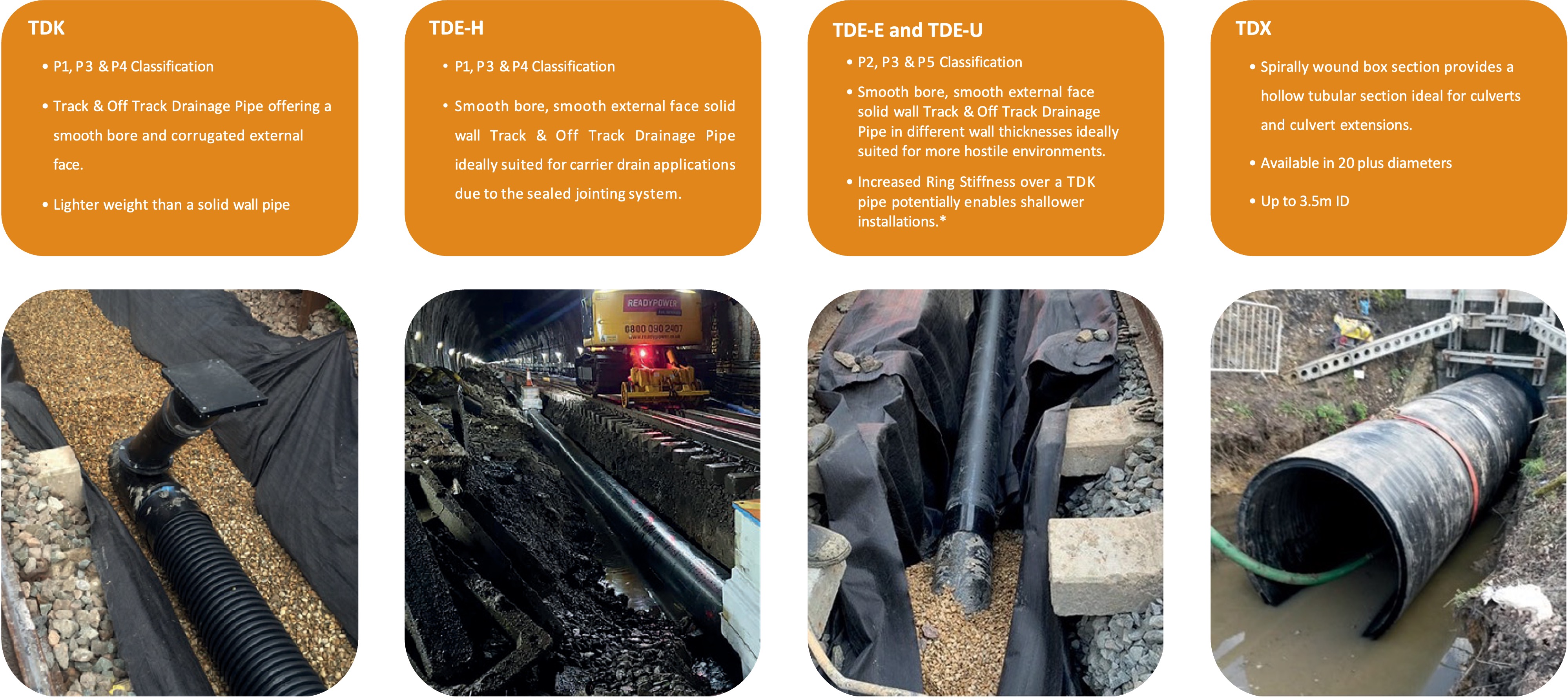

Track Drainage Pipes

With over 30+ years of experience in track drainage we understand that a variety of situations and scenarios exist, resulting in the need for a choice of different drainage pipes to provide the most suitable product for the required application.

NR/L2/CIV/005/09 clause 10.3 states When pipes are used as collector drains, perforations shall be provided along the pipe lengths. Perforations shall be distributed all around the perimeter of the pipe provided that the perforations do not reduce the strength of the pipe structure to below the resistance required.

Network Rail standard detail drawing NR/CIV/SD/322 categorises pipe as either:

- P1 – Standard Perforated Pipe

- P2 – Stronger Perforated Pipe

- P3 – Combined Pipe & Ditch

- P4 – Standard Non-Perforated Pipe

- P5 – Stronger Non-Perforated Pipe

With this in mind, although our three main types of pipe are all manufactured from High Density Polyethylene (HDPE), and comply with BS EN 12666 or 13476, the differing manufacturing processes offer five distinct choices of pipe best suited for a variety of applications. These are:

| TDK |

|

|

TDE-E / TDE-U |

|

TDX |

*Subject to confirmation of suitability through the process of theoretical calculations in line with BS 9295:2020.

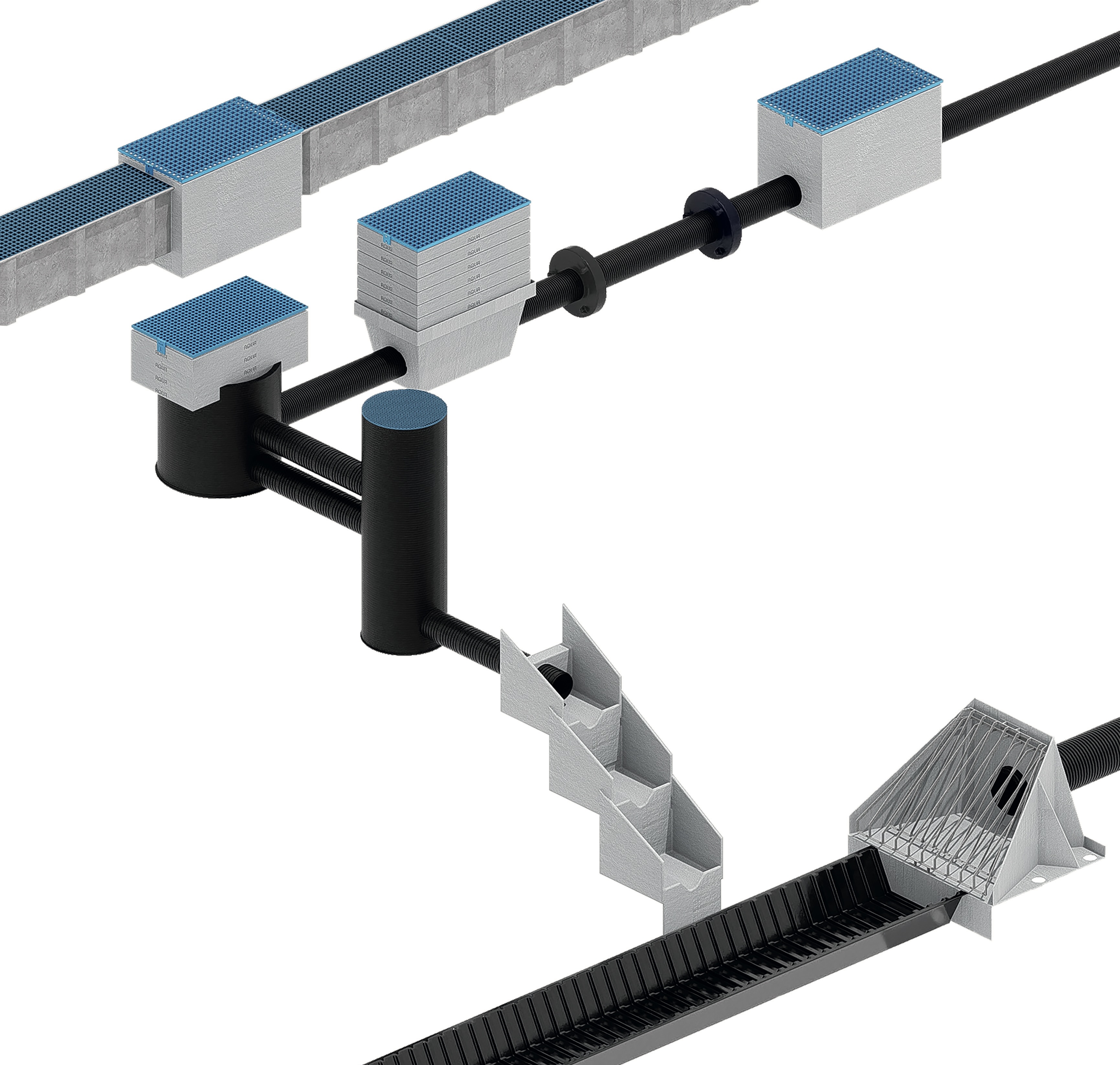

Track Drainage Catch-pits

Credit: Phillip Marsh

A variety of different track drainage catch-pits are available from Aqua including stackable rectangular systems, preformed rectangular systems, hybrid circular/ rectangular units and circular units.

Rectangular Catch-pits

Credit: Phillip Marsh

Developed over the past 20+ years, our Glass Reinforced Plastic (GRP) range of catch-pit sumps, raising frames and covers represent a revolutionary development within the field of railway catch-pit design and construction.

Our range of GRP Catch-pit products are...

- 75 - 90% quicker to install than the equivalent concrete system.

- available for installation with three different sizes of Derby GRP Catch-pit Frames: ‘Narrow’ (‘Matisa’ equivalent), ‘Luton’ and ‘Standard’.

- compatible with Precast Concrete Catch-pit frames, in both Narrow and Standard sizes

- also available as a Modular Derby Chambers for increased flexibility on site.

- available in a range of preformed GRP sump unit sizes to suit a variety of requirements:

- available as a stronger, more durable Deepdale Derby sump unit/ catch-pit unit.

Hybrid Circular/ Rectangular Catch-pits

Although rectangular catch-pits are the ‘norm’ they aren’t always the most effective or efficient solution.

Stafford Hybrid Catch-pits are the most flexible catch-pit system available, combining the benefits of a modular construction with the ease of a bespoke manufactured solution, delivered in ‘off-the-shelf’ timescales.

Also available are heavier duty Somerton Hybrid Catch-pits, manufactured from stronger solid wall material for improved load bearing capabilities.

Circular Catch-pits

SE Catch-pits are a fabricated double skinned tubular section catch-pit/ manhole unit manufactured to suit site specific depth requirements and typically supplied complete with lid & frame assembly, pre-cut inlet/ outlet holes and standard or Anti-floatation Base.

Above Ground Drainage Materials

Although typically known for our below ground drainage products, a wide range of above ground drainage materials are now available from Aqua.

We are proud to introduce three innovative alternatives to traditional concrete products:

Lighter, easier to manhandle and install than their concrete contemporaries and therefore safer and more environmentally friendly to use.

These new, innovative composite products utilise the latest composite materials and manufacturing techniques to provide designers and engineers with the tools they need to address commonly experienced drainage issues nationwide.

Additionally, solutions are now available for lining and protecting drainage outfall’s and ditches (see Erosion Control & Soil Stabilisation) using new and innovative materials and techniques.